Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

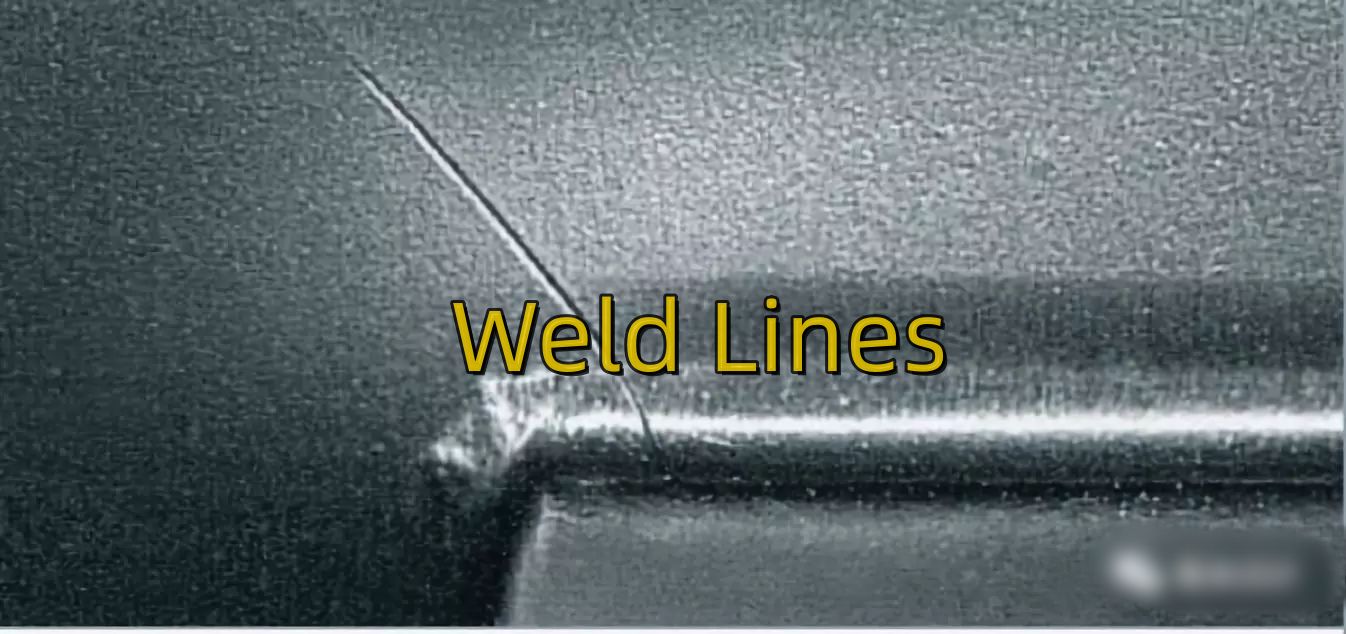

The Most Troublesome Issue in Injection Molding: Weld Lines Defect Analysis and Troubleshooting Methods

Introduction:

Among the many defects found in injection molded products, weld lines are the most common. They occur in most injection molded parts, especially in large, complex products that require multiple gates and inserts. Weld lines not only affect the appearance of the parts but also have varying degrees of impact on their mechanical properties, such as impact strength, tensile strength, and elongation at break. Additionally, weld lines have a significant impact on product design and the lifespan of the parts. Therefore, it is essential to avoid or improve them as much as possible.

Causes and Solutions for Weld Lines:

Low Temperature:Insufficient melt flow convergence occurs when the temperature of the molten plastic is too low, leading to the formation of weld lines. If weld lines appear at the same position on both the internal and external surfaces of the part, it is often due to inadequate fusion caused by low material temperature. To address this issue, the barrel and nozzle temperatures can be increased, or the injection cycle can be extended to raise the material temperature. Additionally, reducing the flow rate of cooling water in the mold and raising the mold temperature are also recommended.

In general, the strength of the weld line location in the part is weak. By locally heating the corresponding area in the mold that creates the weld lines, the strength of the weld line can be improved.

If low-temperature molding processes are required for specific purposes, increasing the injection speed and pressure can enhance the melt convergence performance. Adding a small amount of lubricant to the material formula can also improve its flowability.

Mold Defects:The structural parameters of the mold's gating system have a significant impact on the fusion condition of the melt, as poor fusion mainly occurs during the melt's flow convergence. Therefore, it is advisable to use gating forms with fewer flows and select gate positions reasonably to avoid inconsistent filling rates and interruptions in material flow. Whenever possible, a single-point gate should be used as it does not create multiple melt streams, making it easier to avoid weld lines.

If the mold has too many or too small gates, incorrect positioning of multiple gates, or a large distance between the gate and the weld line, it will lead to poor fusion and more prominent weld lines on the surface of the parts. To address this, it is advised to reduce the number of gates, optimize gate positions, increase gate cross-sections, introduce auxiliary runners, and enlarge the diameter of the main and sub runners.

To prevent weld lines from occurring due to low-temperature melt injection into the mold cavity, a cold slug well can be designed within the mold while raising the mold temperature.

In addition, the areas where the part's weld lines usually occur may produce flash due to high-pressure molding. As these flash areas do not cause shrinkage voids near the weld lines, they are often not considered as faulty. Instead, a shallow groove can be created on the mold at the location where flash is generated, and the weld lines on the part can be transferred to the additional flash wing. After the part is formed, the flash wing can be removed. This is a commonly used method for troubleshooting weld lines.

Poor Mold Venting:When the melt weld line coincides with the mold closure line or the insert joint, the air squeezed by the multiple melt streams in the cavity can escape through the mold parting line or the insert joint. However, when the weld line does not align with the closure line or the joint and improper venting holes are present, the trapped air within the cavity cannot be expelled. The trapped air bubbles are compressed under high pressure, gradually reducing in volume to a point shape. As the molecular kinetic energy of the compressed air transforms into heat energy under high pressure, the temperature at the melt's convergence point increases. When the temperature is equal to or slightly higher than the decomposition temperature of the raw material, yellow spots appear at the weld line. If the temperature is significantly higher than the decomposition temperature, black spots may appear.

In most cases, these spot defects near the weld lines on the surface of the part repeatedly appear at the same location and consistently occur at the melt convergence points. These spots should not be mistaken for impurities during the operation. The main cause of these spots is poor mold venting, resulting in carbonization points formed after high-temperature decomposition of the melt. To address this issue, first check if the mold venting holes are blocked by solidified material or other objects, and if there are any foreign objects at the gate. If blockages are cleared but carbonization points still appear, additional venting holes should be added at the melt convergence points. Alternately, the gate position can be modified or the clamping force can be appropriately reduced to increase the venting clearance. In terms of process operation, auxiliary measures such as reducing material and mold temperatures, shortening high-pressure injection time, and lowering injection pressure can also be adopted.

Improper Use of Mold Release Agent:Excessive use of mold release agent or selecting the wrong type can result in weld lines on the surface of the parts. In injection molding, a small amount of mold release agent is generally applied evenly only to areas such as threads that are difficult to demold. In principle, the use of mold release agent should be minimized.

The selection of various mold release agents must be determined according to molding conditions, part geometry, and material types. For example, pure zinc stearate can be used for various plastics except polyamide and transparent materials. However, when mixed with oil, it can be used for polyamide and transparent plastics. Silica oil toluene solution can be applied to various plastics, and it can be used for a long time after a single application. However, post-application heating and drying are necessary, making it a more complex process.

Unreasonable Part Design:If the wall thickness of the part is designed to be too thin, resulting in a large thickness difference, or if too many inserts are used, it can lead to poor fusion. In the case of thin-walled parts, defects can occur due to rapid solidification of the melt, and weld lines are inevitably formed in areas where the melt converges during the filling process. Once weld lines occur in these areas, the strength of the part is reduced, affecting its performance. Therefore, when designing the shape and structure of the part, it is crucial to ensure that the thinnest section of the part is greater than the minimum allowed thickness during molding. Additionally, the use of inserts should be minimized, and the wall thickness should be as consistent as possible.

Conclusion:

Weld lines are a common issue in injection molding that can affect the quality, mechanical properties, and lifespan of the molded parts. Understanding the causes and implementing appropriate solutions can significantly reduce or eliminate the occurrence of weld lines. By carefully considering factors such as material temperature, mold design, venting, mold release agent usage, and part geometry, manufacturers can produce high-quality injection molded parts with minimal weld line defects.

Product:

https://www.toponew.com/products/abs-compound

https://www.toponew.com/products/pp-compound