Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

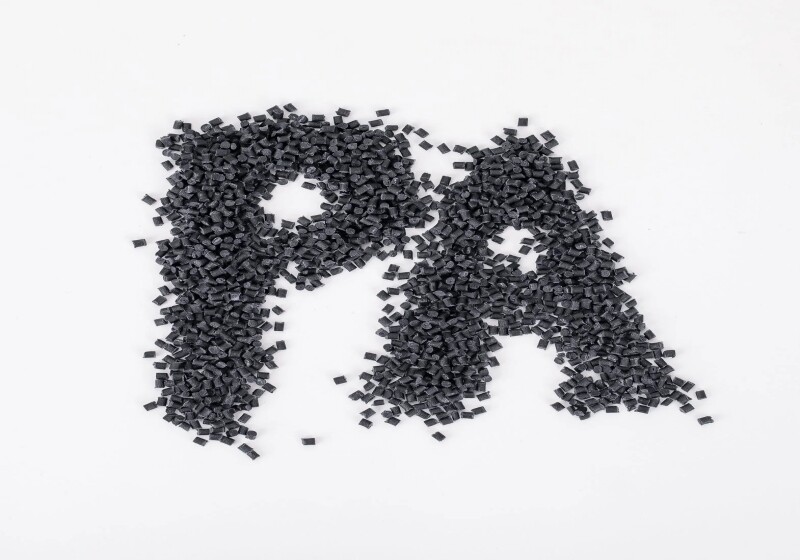

PA66 Granules Fabrication Process

Introduction:

PA66 granules, also known as Nylon 66 granules, are integral to the manufacturing process of various textile and plastic products. Derived from the synthesis of Nylon 66 through polycondensation, PA66 granules offer exceptional strength, durability, and affordability, making them highly sought after in industries such as textiles and plastics.

I. Synthesis of Nylon 66 through Polycondensation:

A. Composition:

1. Nylon 66 consists of two monomers: hexamethylenediamine and adipic acid.

2. These monomers each contain six carbon atoms, resulting in the name nylon 6-6.

B. Polycondensation Process:

1. Hexamethylenediamine and adipic acid are combined in water in equal amounts.

2. The mixture forms an ammonium/carboxylate salt.

3. The salt is heated either in batches or continuously to induce polycondensation.

4. Water is removed, leading to the formation of amide bonds and polymerization of Nylon 66.

II. Obtaining PA66 Granules:

A. Extrusion and Granulation Method:

1. The synthesized nylon material is melted and passed through an extruder.

2. The molten nylon is forced through a die, resulting in granules of specific sizes.

3. These granules can be easily stored, transported, and used in plastic component production.

B. Extrusion Spinning Method:

1. The synthesized nylon material is melted and forced through a spinneret.

2. The spinneret is a small metal plate with fine holes.

3. The emerging nylon is rapidly cooled, solidifying into filaments.

4. These filaments can be processed further to create textile yarns.

III. Application in Industries:

A. Plastic Industry:

1. PA66 granules can be molded, injection-molded, or used in 3D printing processes.

2. They are utilized in the production of automotive parts, electrical connectors, and consumer goods.

B. Textile Industry:

1. PA66 granules are transformed into nylon threads or fibers.

2. These threads are used for weaving fabrics, creating garments, and manufacturing industrial textiles.

Conclusion:

The fabrication process of PA66 granules plays a crucial role in the production of textiles and plastic components. The synthesis of Nylon 66 through polycondensation, followed by the extrusion and granulation or extrusion spinning methods, provides versatile and affordable materials for various industries. With their exceptional physical characteristics, PA66 granules derived from Nylon 66 continue to be in high demand, cementing their prominence in textile and plastic manufacturing sectors.

https://en.wikipedia.org/wiki/Nylon_66

https://www.toponew.com/products/pa66-compound