Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

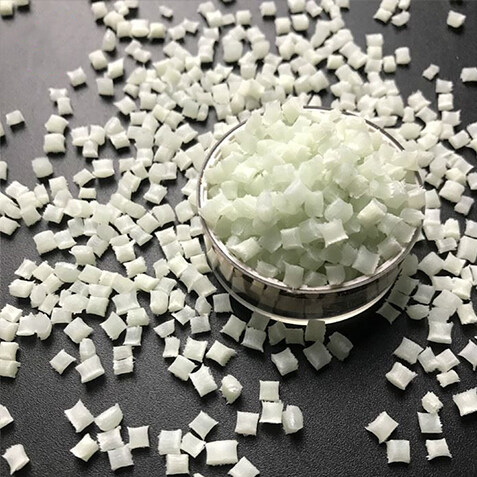

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Color Change: Causes and Solutions

Introduction:

Color change, also known as color streaks, refers to the inconsistency between the molded products and the standard color. Analyzing and troubleshooting color change and color streaks can be done through the following methods:

-

Mold Defects:

If contaminants such as oil, mold release agents, or friction debris from ejector pins mixing into the plastic melt, uneven mold cooling, or poor venting in the mold, it can result in discoloration of the plastic surface. Therefore, before injection molding, it is essential to ensure the cleanliness of the mold cavity. You can consider reducing the clamping force appropriately, repositioning the gate, or placing venting holes at the last filling point. -

Improper Process Conditions:

Incorrect screw speed, excessive injection back pressure, high injection pressure, prolonged injection and holding time, rapid injection speed, dead spots in the barrel, and excessive lubricant usage can cause uneven color on the plastic surface. If there is residual charred material at the nozzle, lowering the nozzle temperature is recommended. For adjusting process parameters such as screw speed, back pressure, injection pressure, injection and holding time, etc., fine-tuning should be done based on the actual situation using a step-by-step approach. -

Inappropriate Material Selection:

Uneven distribution of pigments or the use of pigments that do not meet the requirements can result in uneven color near the feed opening or weld areas. Therefore, when selecting colorants, it is important to carefully consider the process conditions and the desired color requirements for the plastic component.

If the material contains a high content of volatile components, it is mixed with other plastics or poorly dried. In the case of fiber-reinforced materials, uneven distribution of fiber fillers or exposed fibers can lead to uneven color. Additionally, if the resin has excellent crystallization properties, it may affect the transparency of the plastic component, resulting in uneven color on the surface. Therefore, it is crucial to address each specific situation accordingly by implementing appropriate solutions.

By understanding the possible causes and implementing the suggested solutions, color change and color streaks can be effectively mitigated, ensuring consistent and satisfactory product aesthetics.